联系人:张经理

移动电话:15862538293

电话:0512-62650893

传真:0512-62650891

邮箱:sunny@ptitech.com.cn

网址:http://www.ptitech.com.cn

地址:苏州工业园区和顺路29号

PTI816s InLine式在线测试仪,其主要功能为电路板静态测试与FCT功能测试,可多连板自动区分良品与不良品板,达到自动化测试的目的。PTI816s InLine可精简人力,缩短测试时间并提高产能 。

全国服务热线:0512-62650893

在线咨询In Line式在线测试仪

技术参数 Technical Date

★设备效率:900~1200PCS/H

★设备精度(mm):±0.3mm

★伺服系统:三菱

★PLC控制:三菱

★人机界面:信捷

★丝杆/导轨:采用HIWIN精密滚珠丝杆和直线加宽导轨

★减速机:TWT

★气动元件:SMC(日本)或亚德客

★D:OMROM或基恩士

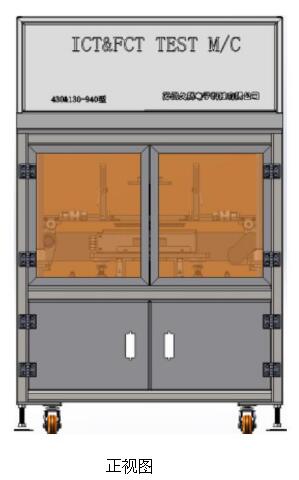

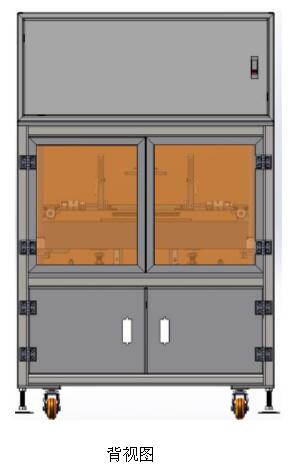

★设备外形尺寸:1850mm(L)*1300mm(W)*1700(H)mm

★设备总重量:约400KG Total

★设备总功率:约0.37KW Total

★气压(Mpa):0.4~0.6Mpa

★工作电压:AC220V50~60HZ

★Equipment efficiency: 900 ~ 1200PCS / H

★Equipment Accuracy (mm): ± 0.3mm

★Servosystem: Mitsubishi

★PLC control system: Mitsubishi

★HMI: XINJE

★Screw / rail: The HIWIN precision ball screw & Straight line widening

★Reducer: TWT

★Pneumatic components: SMC (Japan) or Airtac

★D: OMRON or Keyence

★Equipment Dimensions: 1850mm (*) * 1300mm (W) * 1700 (H) mm

★Total weight: about 400KG

★Total power: about 0.37KW

★Air pressure (Mpa): 0.4 ~ 0.6Mpa

★Operating voltage: AC220V50 ~ 60HZ

功能介绍 Function Ineroduction

★全自动INLINE设计方式,无需人工操作

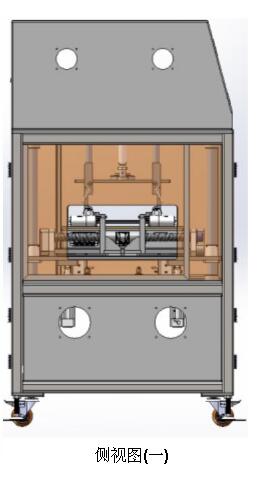

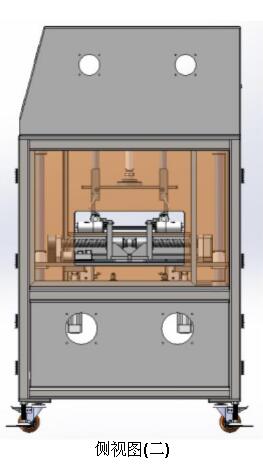

★ICT静态+动态测试(根据客户需求配备)

★自动区分良品/不良品产品。

★自动读写条码功能(根据客户需求配备扫描枪或CCD)

★测试前PCBA方向检测

★测试速度比手工快30%以上,无人化作业,比手工操作减少1人

★ICT测试治具只需修改载板可直接安装使用

★Designed by full-automatic,Manual operation un-necessary

★ICT Static&Dynamic testing(According to customers requirements

★Distinguished PASS OR FAIL products automatically.

★Bar-code reading automatically.( According customer's requirements to provide scanner or CCD)

★PCBA direction confrimed before testing.

★Faster than manual testing about 30% or more, unmanned operation than manual operation reduced 1 operator at least.

★ICT test fixture can be installed directly just modify the carrier plate .

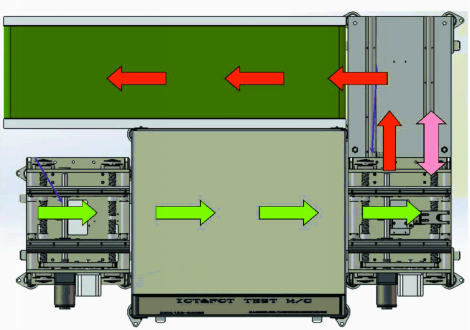

设备运行流程 Running Processes of equipent

待测产品及PASS产品运行方向

Running direction of untreated and PASS products

FAIL产品运行方向

Running direction of FAIL products

移栽机运行方向

Running direction ofTransfer machine

移栽机Transfer machine

待测产品等待工位(此工位完成条码读写及PCBA方向检测)

The waiting station of not test products(It can complete the Bar code reading and PCBA direction detection)

ICT OR FCT

检测机TESTER

设备视图 Equipent view